Page 263 - Plastics Engineering

P. 263

246 Processing of Plastics

4.2 Extrusion

4.2.1 General Features of Single Screw Extrusion

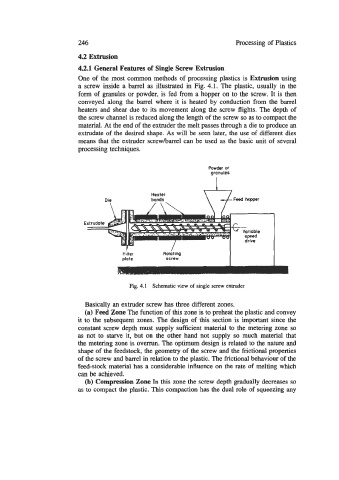

One of the most common methods of processing plastics is Extrusion using

a screw inside a barrel as illustrated in Fig. 4.1. The plastic, usually in the

form of granules or powder, is fed from a hopper on to the screw. It is then

conveyed along the barrel where it is heated by conduction from the barrel

heaters and shear due to its movement along the screw flights. The depth of

the screw channel is reduced along the length of the screw so as to compact the

material. At the end of the extruder the melt passes through a die to produce an

extrudate of the desired shape. As will be seen later, the use of different dies

means that the extruder screwharrel can be used as the basic unit of several

processing techniques.

Powder or

granules

Heoter

Die bands

I .

Filter Rototing

plate screw

. __ - - _-.

Fig. 4.1 Schematic view of single screw extruder

Basically an extruder screw has three different zones.

(a) Feed Zone The function of this zone is to preheat the plastic and convey

it to the subsequent zones. The design of this section is important since the

constant screw depth must supply sufficient material to the metering zone so

as not to starve it, but on the other hand not supply so much material that

the metering zone is overrun. The optimum design is related to the nature and

shape of the feedstock, the geometry of the screw and the frictional properties

of the screw and barrel in relation to the plastic. The frictional behaviour of the

feed-stock material has a considerable influence on the rate of melting which

can be achieved.

(b) Compression Zone In this zone the screw depth gradually decreases so

as to compact the plastic. This compaction has the dual role of squeezing any