Page 264 - Plastics Engineering

P. 264

Processing of Plastics 247

trapped air pockets back into the feed zone and improving the heat transfer

through the reduced thickness of material.

(e) Metering Zone In this section the screw depth is again constant but

much less than the feed zone. In the metering zone the melt is homogenised so

as to supply at a constant rate, material of uniform temperature and pressure

to the die. This zone is the most straight-forward to analyse since it involves a

viscous melt flowing along a uniform channel.

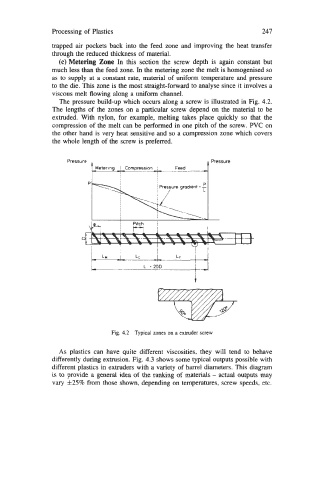

The pressure build-up which occurs along a screw is illustrated in Fig. 4.2.

The lengths of the zones on a particular screw depend on the material to be

extruded. With nylon, for example, melting takes place quickly so that the

compression of the melt can be performed in one pitch of the screw. PVC on

the other hand is very heat sensitive and so a compression zone which covers

the whole length of the screw is preferred.

Pressure Pressure

Metering 1 Compression Feed ..___

I

I

0

Fig. 4.2 Typical zones on a extruder screw

As plastics can have quite different viscosities, they will tend to behave

differently during extrusion. Fig. 4.3 shows some typical outputs possible with

different plastics in extruders with a variety of barrel diameters. This diagram

is to provide a general idea of the ranking of materials - actual outputs may

vary f25% from those shown, depending on temperatures, screw speeds, etc.