Page 266 - Plastics Engineering

P. 266

Processing of Plastics 249

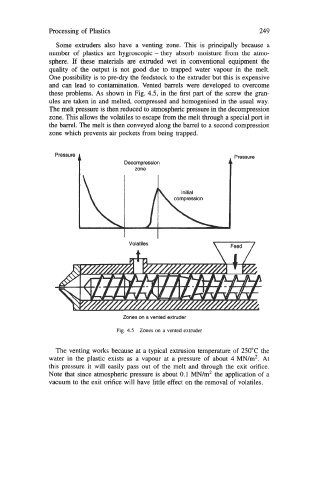

Some extruders also have a venting zone. This is principally because a

number of plastics are hygroscopic - they absorb moisture from the atmo-

sphere. If these materials are extruded wet in conventional equipment the

quality of the output is not good due to trapped water vapour in the melt.

One possibility is to pre-dry the feedstock to the extruder but this is expensive

and can lead to contamination. Vented barrels were developed to overcome

these problems. As shown in Fig. 4.5, in the first part of the screw the gran-

ules are taken in and melted, compressed and homogenised in the usual way.

The melt pressure is then reduced to atmospheric pressure in the decompression

zone. This allows the volatiles to escape from the melt through a special port in

the barrel. The melt is then conveyed along the barrel to a second compression

zone which prevents air pockets from being trapped.

Pressure Pressure

Decompression

zone

Volatiles Feed /

Zones on a vented extruder

Fig. 4.5 Zones on a vented extruder

The venting works because at a typical extrusion temperature of 250°C the

water in the plastic exists as a vapour at a pressure of about 4 MN/m2. At

this pressure it will easily pass out of the melt and through the exit orifice.

Note that since atmospheric pressure is about 0.1 MN/m2 the application of a

vacuum to the exit orifice will have little effect on the removal of volatiles.