Page 267 - Plastics Engineering

P. 267

250 Processing of Plastics

Another feature of an extruder is the presence of a gauze filter after the screw

and before the die. This effectively filters out any inhomogeneous material

which might otherwise clog the die. These screen packs as they are called, will

normally filter the melt to 120-150 pm. However, there is conclusive evidence

to show that even smaller particles than this can initiate cracks in plastics

extrudates e.g. polyethylene pressure pipes. In such cases it has been found

that fine melt filtration (245 pm) can significantly improve the performance

of the extrudate.

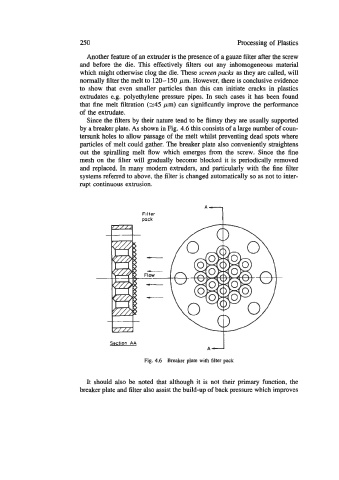

Since the filters by their nature tend to be flimsy they are usually supported

by a breaker plate. As shown in Fig. 4.6 this consists of a large number of coun-

tersunk holes to allow passage of the melt whilst preventing dead spots where

particles of melt could gather. The breaker plate also conveniently straightens

out the spiralling melt flow which emerges from the screw. Since the fine

mesh on the filter will gradually become blocked it is periodically removed

and replaced. In many modem extruders, and particularly with the fine filter

systems referred to above, the filter is changed automatically so as not to inter-

rupt continuous extrusion.

Filter *-l

pack

Section AA

A

Fig. 4.6 Breaker plate with filter pack

It should also be noted that although it is not their primary function, the

breaker plate and filter also assist the build-up of back pressure which improves