Page 358 - Plastics Engineering

P. 358

Processing of Plastics 34 1

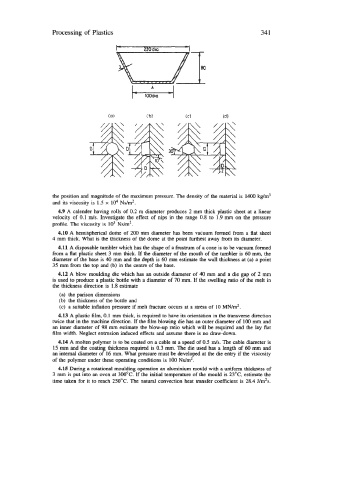

t- 220 dia

4

3

the position and magnitude of the maximum pressure. The density of the material is 1400 kg/m3

and its viscosity is 1.5 x 104 Ns/m2.

4.9 A calender having rolls of 0.2 m diameter produces 2 mm thick plastic sheet at a linear

velocity of 0.1 ds. Investigate the effect of nips in the range 0.8 to 1.9 mm on the pressure

profile. The viscosity is lo3 Ns/m2.

4.10 A hemispherical dome of 200 mm diameter has been vacuum formed from a flat sheet

4 mm thick. What is the thickness of the dome at the point furthest away from its diameter.

4.11 A disposable tumbler which has the shape of a frustrum of a cone is to be vacuum formed

from a flat plastic sheet 3 mm thick. If the diameter of the mouth of the tumbler is 60 mm, the

diameter of the base is 40 mm and the depth is 60 mm estimate the wall thickness at (a) a point

35 mm from the top and (b) in the centre of the base.

4.12 A blow moulding die which has an outside diameter of 40 mm and a die gap of 2 mm

is used to produce a plastic bottle with a diameter of 70 mm. If the swelling ratio of the melt in

the thickness direction is 1.8 estimate

(a) the parison dimensions

(b) the thickness of the bottle and

(c) a suitable inflation pressure if melt fracture occurs at a stress of 10 MN/m2.

4.13 A plastic film, 0.1 mm thick, is required to have its orientation in the transverse direction

twice that in the machine direction. If the film blowing die has an outer diameter of 100 mm and

an inner diameter of 98 mm estimate the blow-up ratio which will be required and the lay flat

film width. Neglect extrusion induced effects and assume there is no draw-down.

4.14 A molten polymer is to be. coated on a cable at a speed of 0.5 ds. The cable diameter is

15 mm and the coating thickness required is 0.3 mm. The die used has a length of 60 mm and

an internal diameter of 16 mm. What pressure must be developed at the die entry if the viscosity

of the polymer under these operating conditions is 100 Ns/m2.

4.15 During a rotational moulding operation an aluminium mould with a uniform thickness of

3 mm is put into an oven at 300°C. If the initial temperature of the mould is 23°C. estimate the

time taken for it to reach 250°C. The natural convection heat transfer coefficient is 28.4 J/m2s.