Page 353 - Plastics Engineering

P. 353

336 Processing of Plastics

&

Heater

Laminate

Laminate

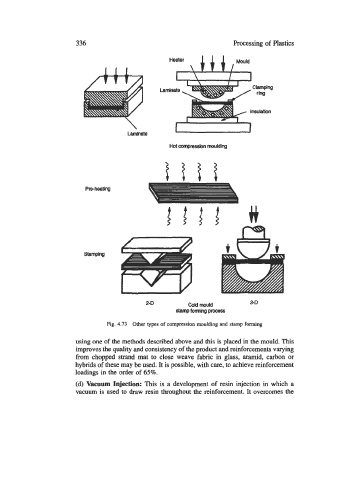

Hot compression moulding

1

2-0 Cold muid 3-D

stamp f0llnlng process

Fig. 4.73 Other types of compression moulding and stamp forming

using one of the methods described above and this is placed in the mould. This

improves the quality and consistency of the product and reinforcements varying

from chopped strand mat to close weave fabric in glass, aramid, carbon or

hybrids of these may be used. It is possible, with care, to achieve reinforcement

loadings in the order of 65%.

(d) Vacuum Injection: This is a development of resin injection in which a

vacuum is used to draw resin throughout the reinforcement. It overcomes the