Page 352 - Plastics Engineering

P. 352

Processing of Plastics 335

Canier

film

Continuous

Canier Take - up roll

film for SMC

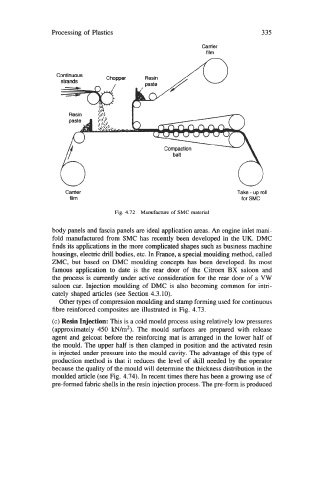

Fig. 4.72 Manufacture of SMC material

body panels and fascia panels are ideal application areas. An engine inlet mani-

fold manufactured from SMC has recently been developed in the UK. DMC

finds its applications in the more complicated shapes such as business machine

housings, electric drill bodies, etc. In France, a special moulding method, called

ZMC, but based on DMC moulding concepts has been developed. Its most

famous application to date is the rear door of the Citroen BX saloon and

the process is currently under active consideration for the rear door of a VW

saloon car. Injection moulding of DMC is also becoming common for intri-

cately shaped articles (see Section 4.3.10).

Other types of compression moulding and stamp forming used for continuous

fibre reinforced composites are illustrated in Fig. 4.73.

(c) Resin Injection: This is a cold mould process using relatively low pressures

(approximately 450 kN/m2). The mould surfaces are prepared with release

agent and gelcoat before the reinforcing mat is arranged in the lower half of

the mould. The upper half is then clamped in position and the activated resin

is injected under pressure into the mould cavity. The advantage of this type of

production method is that it reduces the level of skill needed by the operator

because the quality of the mould will determine the thickness distribution in the

moulded article (see Fig. 4.74). In recent times there has been a growing use of

pre-formed fabric shells in the resin injection process. The pre-form is produced