Page 351 - Plastics Engineering

P. 351

334 Processing of Plastics

Y P P fibres of

l

Y

Supply of

', p,rotated (b)

Heated

mould

Exhaust \ \ \

fan Preform \, 63

transferred \ /p

(a) to mould \,,

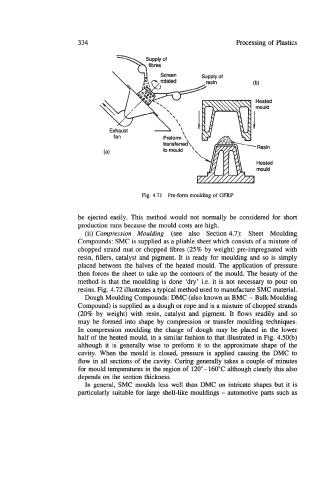

Fig. 4.71 Re-form moulding of GFRP

be ejected easily. This method would not normally be considered for short

production runs because the mould costs are high.

(ii) Compression Moulding (see also Section 4.7): Sheet Moulding

Compounds: SMC is supplied as a pliable sheet which consists of a mixture of

chopped strand mat or chopped fibres (25% by weight) pre-impregnated with

resin, fillers, catalyst and pigment. It is ready for moulding and so is simply

placed between the halves of the heated mould. The application of pressure

then forces the sheet to take up the contours of the mould. The beauty of the

method is that the moulding is done 'dry' i.e. it is not necessary to pour on

resins. Fig. 4.72 illustrates a typical method used to manufacture SMC material.

Dough Moulding Compounds: DMC (also known as BMC - Bulk Moulding

Compound) is supplied as a dough or rope and is a mixture of chopped strands

(20% by weight) with resin, catalyst and pigment. It flows readily and so

may be formed into shape by compression or transfer moulding techniques.

In compression moulding the charge of dough may be placed in the lower

half of the heated mould, in a similar fashion to that illustrated in Fig. 4.50(b)

although it is generally wise to preform it to the approximate shape of the

cavity. When the mould is closed, pressure is applied causing the DMC to

flow in all sections of the cavity. Curing generally takes a couple of minutes

for mould temperatures in the region of 12W-160"C although clearly this also

depends on the section thickness.

In general, SMC moulds less well than DMC on intricate shapes but it is

particularly suitable for large shell-like mouldings - automotive parts such as