Page 348 - Plastics Engineering

P. 348

Processing of Plastics 33 1

Resin brushed on

cures inair

Layers of

resin ond

fibres

(a1 Basic hand lay-up method

Flexible bag

Mould / Mould V. ‘Mwld

ng

I

IbIVacuum bag (cl Pressure bog

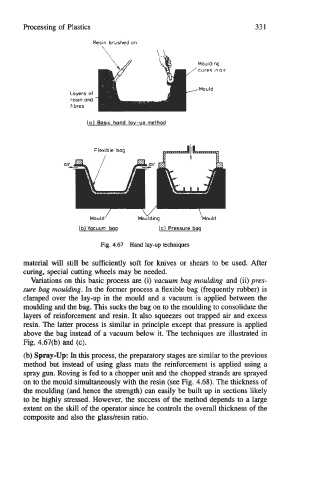

Fig. 4.67 Hand lay-up techniques

material will still be sufficiently soft for knives or shears to be used. After

curing, special cutting wheels may be needed.

Variations on this basic process are (i) vacuum bug moulding and (ii) pres-

sure bug moulding. In the former process a flexible bag (frequently rubber) is

clamped over the lay-up in the mould and a vacuum is applied between the

moulding and the bag. This sucks the bag on to the moulding to consolidate the

layers of reinforcement and resin. It also squeezes out trapped air and excess

resin. The latter process is similar in principle except that pressure is applied

above the bag instead of a vacuum below it. The techniques are illustrated in

Fig. 4.67(b) and (c).

(b) Spray-Up: In this process, the preparatory stages are similar to the previous

method but instead of using glass mats the reinforcement is applied using a

spray gun. Roving is fed to a chopper unit and the chopped strands are sprayed

on to the mould simultaneously with the resin (see Fig. 4.68). The thickness of

the moulding (and hence the strength) can easily be built up in sections likely

to be highly stressed. However, the success of the method depends to a large

extent on the skill of the operator since he controls the overall thickness of the

composite and also the glasshesin ratio.