Page 350 - Plastics Engineering

P. 350

Processing of Plastics 333

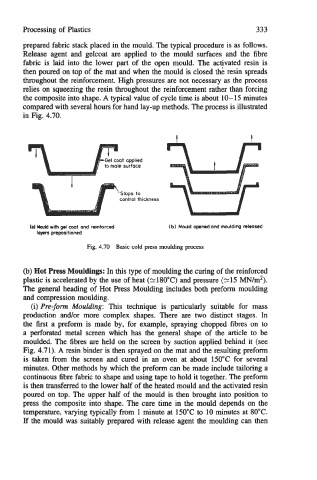

prepared fabric stack placed in the mould. The typical procedure is as follows.

Release agent and gelcoat are applied to the mould surfaces and the fibre

fabric is laid into the lower part of the open mould. The activated resin is

then poured on top of the mat and when the mould is closed thb resin spreads

throughout the reinforcement. High pressures are not necessary as the process

relies on squeezing the resin throughout the reinforcement rather than forcing

the composite into shape. A typical value of cycle time is about 10-15 minutes

compared with several hours for hand lay-up methods. The process is illustrated

in Fig. 4.70.

cantrol thickness

lo1 would with gel coat and reinforced I bl Mould opend and moulding released

layers pnpositioned

Fig. 4.70 Basic cold press moulding process

(b) Hot Press Mouldings: In this type of moulding the curing of the reinforced

plastic is accelerated by the use of heat (2:18OoC) and pressure (-15 MN/m2).

The general heading of Hot Press Moulding includes both preform moulding

and compression moulding.

(i) Pre-fom Moulding: This technique is particularly suitable for mass

production and/or more complex shapes. There are two distinct stages. In

the first a preform is made by, for example, spraying chopped fibres on to

a perforated metal screen which has the general shape of the article to be

moulded. The fibres are held on the screen by suction applied behind it (see

Fig. 4.71). A resin binder is then sprayed on the mat and the resulting preform

is taken from the screen and cured in an oven at about 150°C for several

minutes. Other methods by which the preform can be made include tailoring a

continuous fibre fabric to shape and using tape to hold it together. The preform

is then transferred to the lower half of the heated mould and the activated resin

poured on top. The upper half of the mould is then brought into position to

press the composite into shape. The cure time in the mould depends on the

temperature, varying typically from 1 minute at 150°C to 10 minutes at 80°C.

If the mould was suitably prepared with release agent the moulding can then