Page 349 - Plastics Engineering

P. 349

332 Processing of Plastics

Chopped fibre

Mould ’ ‘ Moulding

Fig. 4.68 Spray-up technique

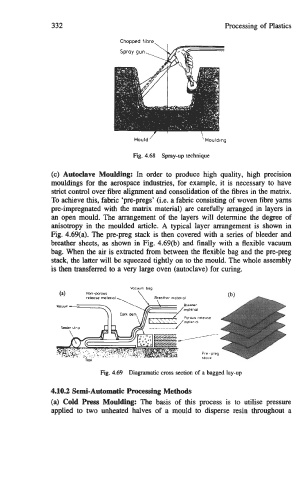

(c) Autoclave Moulding: In order to produce high quality, high precision

mouldings for the aerospace industries, for example, it is necessary to have

strict control over fibre alignment and consolidation of the fibres in the matrix.

To achieve this, fabric ‘pre-pregs’ (i.e. a fabric consisting of woven fibre yarns

pre-impregnated with the matrix material) are carefully arranged in layers in

an open mould. The arrangement of the layers will determine the degree of

anisotropy in the moulded article. A typical layer arrangement is shown in

Fig. 4.69(a). The pre-preg stack is then covered with a series of bleeder and

breather sheets, as shown in Fig. 4.69(b) and finally with a flexible vacuum

bag. When the air is extracted from between the flexible bag and the pre-preg

stack, the latter will be squeezed tightly on to the mould. The whole assembly

is then transferred to a very large oven (autoclave) for curing.

Pwous releose

Fig. 4.69 Diagramatic cross section of a bagged lay-up

4.10.2 Semi-Automatic Processing Methods

(a) Cold Press Moulding: The basis of this process is to utilise pressure

applied to two unheated halves of a mould to disperse resin throughout a