Page 46 - Plastics Engineering

P. 46

General Properties of Plastics 29

shows typical primary wear rates for different plastics, the mechanism of wear

is complex the relative wear rates may change depending on specific circum-

stances.

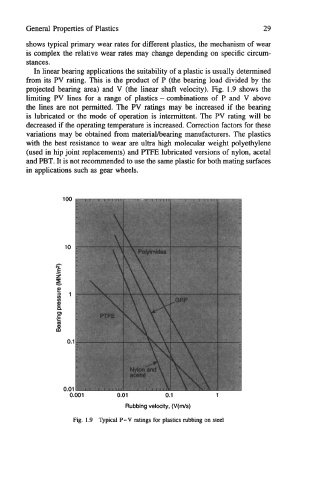

In linear bearing applications the suitability of a plastic is usually determined

from its PV rating. This is the product of P (the bearing load divided by the

projected bearing area) and V (the linear shaft velocity). Fig. 1.9 shows the

limiting PV lines for a range of plastics - combinations of P and V above

the lines are not permitted. The PV ratings may be increased if the bearing

is lubricated or the mode of operation is intermittent. The PV rating will be

decreased if the operating temperature is increased. Correction factors for these

variations may be obtained from materialhearing manufacturers. The plastics

with the best resistance to wear are ultra high molecular weight polyethylene

(used in hip joint replacements) and PTFE lubricated versions of nylon, acetal

and PBT. It is not recommended to use the same plastic for both mating surfaces

in applications such as gear wheels.

Rubbing velocity, (V(ds)

Fig. 1.9 Qpical P-V ratings for plastics rubbing on steel