Page 50 - Plastics Engineering

P. 50

General Properties of Plastics 33

250

$150

-

0

a

El 100

€

B

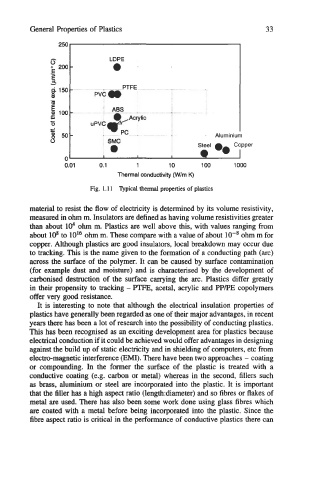

Fig. 1.1 1 lsrpical thermal propexties of plastics

material to resist the flow of electricity is determined by its volume resistivity,

measured in ohm m. Insulators are defined as having volume resistivities greater

than about 104 ohm m. Plastics are well above this, with values ranging from

about 108 to 10l6 ohm m. These compare with a value of about ohm m for

copper. Although plastics are good insulators, local breakdown may occur due

to tracking. This is the name given to the formation of a conducting path (arc)

across the surface of the polymer. It can be caused by surface contamination

(for example dust and moisture) and is characterised by the development of

carbonised destruction of the surface carrying the arc. Plastics differ greatly

in their propensity to tracking - PTFE, acetal, acrylic and PP/PE copolymers

offer very good resistance.

It is interesting to note that although the electrical insulation properties of

plastics have generally been regarded as one of their major advantages, in recent

years there has been a lot of research into the possibility of conducting plastics.

This has been recognised as an exciting development area for plastics because

electrical conduction if it could be achieved would offer advantages in designing

against the build up of static electricity and in shielding of computers, etc from

electro-magnetic interference (EM). There have been two approaches - coating

or compounding. In the former the surface of the plastic is treated with a

conductive coating (e.g. carbon or metal) whereas in the second, fillers such

as brass, aluminium or steel are incorporated into the plastic. It is important

that the filler has a high aspect ratio (1ength:diameter) and so fibres or flakes of

metal are used. There has also been some work done using glass fibres which

are coated with a metal before being incorporated into the plastic. Since the

fibre aspect ratio is critical in the performance of conductive plastics there can