Page 38 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 38

Introduction of polymer-based nanocomposites 17

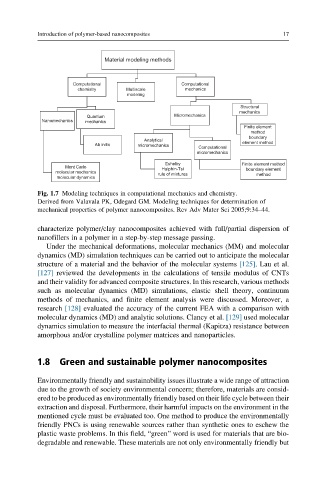

Material modeling methods

Computational Computational

chemistry Multiscale mechanics

modeling

Structural

mechanics

Quantum Micromechanics

Nanomechanics mechanics

Finite element

method

boundary

Analytical

Ab initio micromechanics element method

Computational

micromechanics

Eshelby Finite element method

Mont Carlo Halphin-Tsi boundary element

molecular mechanics rule of mixtures method

molecular dynamics

Fig. 1.7 Modeling techniques in computational mechanics and chemistry.

Derived from Valavala PK, Odegard GM. Modeling techniques for determination of

mechanical properties of polymer nanocomposites. Rev Adv Mater Sci 2005;9:34–44.

characterize polymer/clay nanocomposites achieved with full/partial dispersion of

nanofillers in a polymer in a step-by-step message passing.

Under the mechanical deformations, molecular mechanics (MM) and molecular

dynamics (MD) simulation techniques can be carried out to anticipate the molecular

structure of a material and the behavior of the molecular systems [125]. Lau et al.

[127] reviewed the developments in the calculations of tensile modulus of CNTs

and their validity for advanced composite structures. In this research, various methods

such as molecular dynamics (MD) simulations, elastic shell theory, continuum

methods of mechanics, and finite element analysis were discussed. Moreover, a

research [128] evaluated the accuracy of the current FEA with a comparison with

molecular dynamics (MD) and analytic solutions. Clancy et al. [129] used molecular

dynamics simulation to measure the interfacial thermal (Kapitza) resistance between

amorphous and/or crystalline polymer matrices and nanoparticles.

1.8 Green and sustainable polymer nanocomposites

Environmentally friendly and sustainability issues illustrate a wide range of attraction

due to the growth of society environmental concern; therefore, materials are consid-

ered to be produced as environmentally friendly based on their life cycle between their

extraction and disposal. Furthermore, their harmful impacts on the environment in the

mentioned cycle must be evaluated too. One method to produce the environmentally

friendly PNCs is using renewable sources rather than synthetic ones to eschew the

plastic waste problems. In this field, “green” word is used for materials that are bio-

degradable and renewable. These materials are not only environmentally friendly but