Page 461 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 461

418 Polymer-based Nanocomposites for Energy and Environmental Applications

forces the dispersion medium of the sol to flow into the dry part of the support. The sol

particles are concerned at the entrance of the pores, and a gel is formed. This gel can be

dried and calcined to form a crack-free alumina membrane with pores measuring only

a few nanometers, if the membrane thickness after calcination is about 5 μm or less.

The gel formation process can be quantitatively well described with the slip-casting

model. The explanations that the membrane thickness rises linearly with the square

root of the dipping time, the casting rate increases if the sol concentration increases,

and the pore size of the support decreases or the gelling concentration decreases are all

in accordance with this slip-casting model.

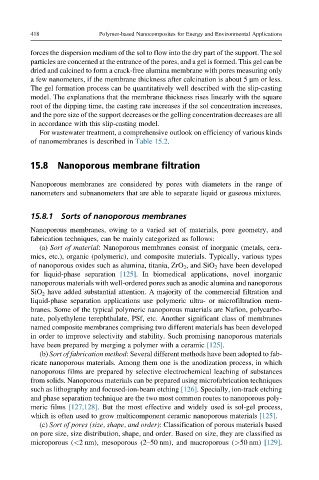

For wastewater treatment, a comprehensive outlook on efficiency of various kinds

of nanomembranes is described in Table 15.2.

15.8 Nanoporous membrane filtration

Nanoporous membranes are considered by pores with diameters in the range of

nanometers and subnanometers that are able to separate liquid or gaseous mixtures.

15.8.1 Sorts of nanoporous membranes

Nanoporous membranes, owing to a varied set of materials, pore geometry, and

fabrication techniques, can be mainly categorized as follows:

(a) Sort of material: Nanoporous membranes consist of inorganic (metals, cera-

mics, etc.), organic (polymeric), and composite materials. Typically, various types

of nanoporous oxides such as alumina, titania, ZrO 2 , and SiO 2 have been developed

for liquid-phase separation [125]. In biomedical applications, novel inorganic

nanoporous materials with well-ordered pores such as anodic alumina and nanoporous

SiO 2 have added substantial attention. A majority of the commercial filtration and

liquid-phase separation applications use polymeric ultra- or microfiltration mem-

branes. Some of the typical polymeric nanoporous materials are Nafion, polycarbo-

nate, polyethylene terephthalate, PSf, etc. Another significant class of membranes

named composite membranes comprising two different materials has been developed

in order to improve selectivity and stability. Such promising nanoporous materials

have been prepared by merging a polymer with a ceramic [125].

(b) Sort of fabrication method: Several different methods have been adopted to fab-

ricate nanoporous materials. Among them one is the anodization process, in which

nanoporous films are prepared by selective electrochemical leaching of substances

from solids. Nanoporous materials can be prepared using microfabrication techniques

such as lithography and focused-ion-beam etching [126]. Specially, ion-track etching

and phase separation technique are the two most common routes to nanoporous poly-

meric films [127,128]. But the most effective and widely used is sol-gel process,

which is often used to grow multicomponent ceramic nanoporous materials [125].

(c) Sort of pores (size, shape, and order): Classification of porous materials based

on pore size, size distribution, shape, and order. Based on size, they are classified as

microporous (<2 nm), mesoporous (2–50 nm), and macroporous (>50 nm) [129].