Page 51 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 51

30 Polymer-based Nanocomposites for Energy and Environmental Applications

Melt

intercalation Hydrothermal Template

synthesis

synthesis synthesis

Chemical

vapor

deposition Nano materials High energy ball

preparation milling process

method (HEBM)

Complex

polymerized

method

RSP with

Microwave Rapid solidification

synthesis process (RSP) ultrasonic

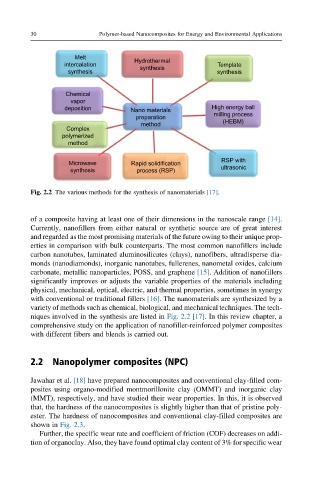

Fig. 2.2 The various methods for the synthesis of nanomaterials [17].

of a composite having at least one of their dimensions in the nanoscale range [14].

Currently, nanofillers from either natural or synthetic source are of great interest

and regarded as the most promising materials of the future owing to their unique prop-

erties in comparison with bulk counterparts. The most common nanofillers include

carbon nanotubes, laminated aluminosilicates (clays), nanofibers, ultradisperse dia-

monds (nanodiamonds), inorganic nanotubes, fullerenes, nanometal oxides, calcium

carbonate, metallic nanoparticles, POSS, and graphene [15]. Addition of nanofillers

significantly improves or adjusts the variable properties of the materials including

physical, mechanical, optical, electric, and thermal properties, sometimes in synergy

with conventional or traditional fillers [16]. The nanomaterials are synthesized by a

variety of methods such as chemical, biological, and mechanical techniques. The tech-

niques involved in the synthesis are listed in Fig. 2.2 [17]. In this review chapter, a

comprehensive study on the application of nanofiller-reinforced polymer composites

with different fibers and blends is carried out.

2.2 Nanopolymer composites (NPC)

Jawahar et al. [18] have prepared nanocomposites and conventional clay-filled com-

posites using organo-modified montmorillonite clay (OMMT) and inorganic clay

(MMT), respectively, and have studied their wear properties. In this, it is observed

that, the hardness of the nanocomposites is slightly higher than that of pristine poly-

ester. The hardness of nanocomposites and conventional clay-filled composites are

shown in Fig. 2.3.

Further, the specific wear rate and coefficient of friction (COF) decreases on addi-

tion of organoclay. Also, they have found optimal clay content of 3% for specific wear