Page 54 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 54

Preparation and properties of nanopolymer advanced composites: A review 33

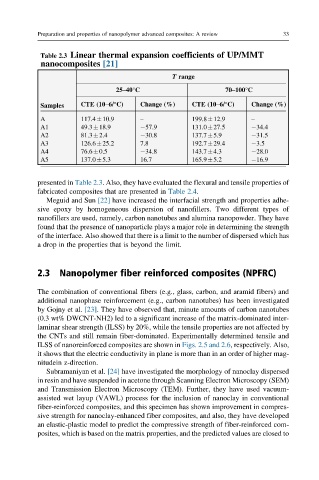

Table 2.3 Linear thermal expansion coefficients of UP/MMT

nanocomposites [21]

T range

25–40°C 70–100°C

Samples CTE (10–6/°C) Change (%) CTE (10–6/°C) Change (%)

A 117.4 10.9 – 199.8 12.9 –

A1 49.3 18.9 57.9 131.0 27.5 34.4

A2 81.3 2.4 30.8 137.7 5.9 31.5

A3 126.6 25.2 7.8 192.7 29.4 3.5

A4 76.6 0.5 34.8 143.7 4.3 28.0

A5 137.0 5.3 16.7 165.9 5.2 16.9

presented in Table 2.3. Also, they have evaluated the flexural and tensile properties of

fabricated composites that are presented in Table 2.4.

Meguid and Sun [22] have increased the interfacial strength and properties adhe-

sive epoxy by homogeneous dispersion of nanofillers. Two different types of

nanofillers are used, namely, carbon nanotubes and alumina nanopowder. They have

found that the presence of nanoparticle plays a major role in determining the strength

of the interface. Also showed that there is a limit to the number of dispersed which has

a drop in the properties that is beyond the limit.

2.3 Nanopolymer fiber reinforced composites (NPFRC)

The combination of conventional fibers (e.g., glass, carbon, and aramid fibers) and

additional nanophase reinforcement (e.g., carbon nanotubes) has been investigated

by Gojny et al. [23]. They have observed that, minute amounts of carbon nanotubes

(0.3 wt% DWCNT-NH2) led to a significant increase of the matrix-dominated inter-

laminar shear strength (ILSS) by 20%, while the tensile properties are not affected by

the CNTs and still remain fiber-dominated. Experimentally determined tensile and

ILSS of nanoreinforced composites are shown in Figs. 2.5 and 2.6, respectively. Also,

it shows that the electric conductivity in plane is more than in an order of higher mag-

nitudein z-direction.

Subramaniyan et al. [24] have investigated the morphology of nanoclay dispersed

in resin and have suspended in acetone through Scanning Electron Microscopy (SEM)

and Transmission Electron Microscopy (TEM). Further, they have used vacuum-

assisted wet layup (VAWL) process for the inclusion of nanoclay in conventional

fiber-reinforced composites, and this specimen has shown improvement in compres-

sive strength for nanoclay-enhanced fiber composites, and also, they have developed

an elastic-plastic model to predict the compressive strength of fiber-reinforced com-

posites, which is based on the matrix properties, and the predicted values are closed to