Page 59 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 59

Preparation and properties of nanopolymer advanced composites: A review 37

22

Laminate with OMMT/epoxy

Laminate with MMT/epoxy

20

Flexural modulus (GPa) 18

16

14

12

0 1 2 3 4 5 6 7 8 9 10 11

Clay content (wt%)

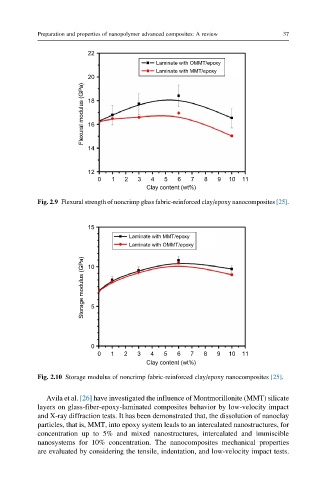

Fig. 2.9 Flexural strength of noncrimp glass fabric-reinforced clay/epoxy nanocomposites [25].

15

Laminate with MMT/epoxy

Laminate with OMMT/epoxy

Storage modulus (GPa) 10

5

0

0 1 2 3 4 5 6 7 8 9 10 11

Clay content (wt%)

Fig. 2.10 Storage modulus of noncrimp fabric-reinforced clay/epoxy nanocomposites [25].

Avila et al. [26] have investigated the influence of Montmorillonite (MMT) silicate

layers on glass-fiber-epoxy-laminated composites behavior by low-velocity impact

and X-ray diffraction tests. It has been demonstrated that, the dissolution of nanoclay

particles, that is, MMT, into epoxy system leads to an intercalated nanostructures, for

concentration up to 5% and mixed nanostructures, intercalated and immiscible

nanosystems for 10% concentration. The nanocomposites mechanical properties

are evaluated by considering the tensile, indentation, and low-velocity impact tests.