Page 63 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 63

Preparation and properties of nanopolymer advanced composites: A review 41

140

130

120

CAI strength (MPa) 100 3% Clay

110

90

5% Clay

0% Clay

80

70

60

50

0 4 8 12 16 20 24 28 32

Impact energy (J)

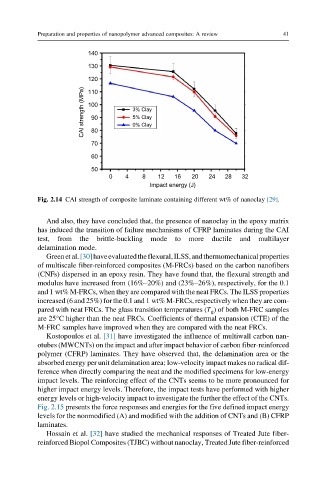

Fig. 2.14 CAI strength of composite laminate containing different wt% of nanoclay [29].

And also, they have concluded that, the presence of nanoclay in the epoxy matrix

has induced the transition of failure mechanisms of CFRP laminates during the CAI

test, from the brittle-buckling mode to more ductile and multilayer

delamination mode.

Greenetal.[30]haveevaluatedtheflexural,ILSS,andthermomechanicalproperties

of multiscale fiber-reinforced composites (M-FRCs) based on the carbon nanofibers

(CNFs) dispersed in an epoxy resin. They have found that, the flexural strength and

modulus have increased from (16%–20%) and (23%–26%), respectively, for the 0.1

and 1 wt% M-FRCs, when they are compared with the neat FRCs. The ILSS properties

increased (6 and 25%) for the 0.1 and 1 wt% M-FRCs, respectively when they are com-

pared with neat FRCs. The glass transition temperatures (T g ) of both M-FRC samples

are 25°C higher than the neat FRCs. Coefficients of thermal expansion (CTE) of the

M-FRC samples have improved when they are compared with the neat FRCs.

Kostopoulos et al. [31] have investigated the influence of multiwall carbon nan-

otubes (MWCNTs) on the impact and after impact behavior of carbon fiber-reinforced

polymer (CFRP) laminates. They have observed that, the delamination area or the

absorbed energy per unit delamination area; low-velocity impact makes no radical dif-

ference when directly comparing the neat and the modified specimens for low-energy

impact levels. The reinforcing effect of the CNTs seems to be more pronounced for

higher impact energy levels. Therefore, the impact tests have performed with higher

energy levels or high-velocity impact to investigate the further the effect of the CNTs.

Fig. 2.15 presents the force responses and energies for the five defined impact energy

levels for the nonmodified (A) and modified with the addition of CNTs and (B) CFRP

laminates.

Hossain et al. [32] have studied the mechanical responses of Treated Jute fiber-

reinforced Biopol Composites (TJBC) without nanoclay, Treated Jute fiber-reinforced