Page 53 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 53

32 Polymer-based Nanocomposites for Energy and Environmental Applications

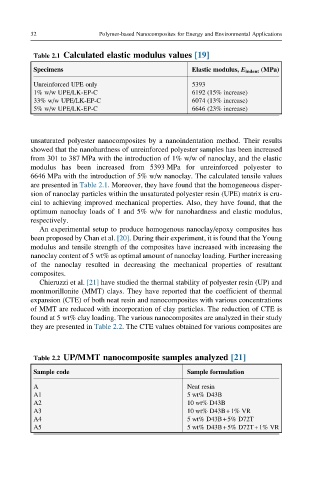

Table 2.1 Calculated elastic modulus values [19]

Specimens Elastic modulus, E indent (MPa)

Unreinforced UPE only 5393

1% w/w UPE/LK-EP-C 6192 (15% increase)

33% w/w UPE/LK-EP-C 6074 (13% increase)

5% w/w UPE/LK-EP-C 6646 (23% increase)

unsaturated polyester nanocomposites by a nanoindentation method. Their results

showed that the nanohardness of unreinforced polyester samples has been increased

from 301 to 387 MPa with the introduction of 1% w/w of nanoclay, and the elastic

modulus has been increased from 5393 MPa for unreinforced polyester to

6646 MPa with the introduction of 5% w/w nanoclay. The calculated tensile values

are presented in Table 2.1. Moreover, they have found that the homogeneous disper-

sion of nanoclay particles within the unsaturated polyester resin (UPE) matrix is cru-

cial to achieving improved mechanical properties. Also, they have found, that the

optimum nanoclay loads of 1 and 5% w/w for nanohardness and elastic modulus,

respectively.

An experimental setup to produce homogenous nanoclay/epoxy composites has

been proposed by Chan et al. [20]. During their experiment, it is found that the Young

modulus and tensile strength of the composites have increased with increasing the

nanoclay content of 5 wt% as optimal amount of nanoclay loading. Further increasing

of the nanoclay resulted in decreasing the mechanical properties of resultant

composites.

Chieruzzi et al. [21] have studied the thermal stability of polyester resin (UP) and

montmorillonite (MMT) clays. They have reported that the coefficient of thermal

expansion (CTE) of both neat resin and nanocomposites with various concentrations

of MMT are reduced with incorporation of clay particles. The reduction of CTE is

found at 5 wt% clay loading. The various nanocomposites are analyzed in their study

they are presented in Table 2.2. The CTE values obtained for various composites are

Table 2.2 UP/MMT nanocomposite samples analyzed [21]

Sample code Sample formulation

A Neat resin

A1 5 wt% D43B

A2 10 wt% D43B

A3 10 wt% D43B+1% VR

A4 5 wt% D43B+5% D72T

A5 5 wt% D43B+5% D72T+1% VR