Page 621 - Polymer-based Nanocomposites for Energy and Environmental Applications

P. 621

Polymer nanocomposites for water treatments 573

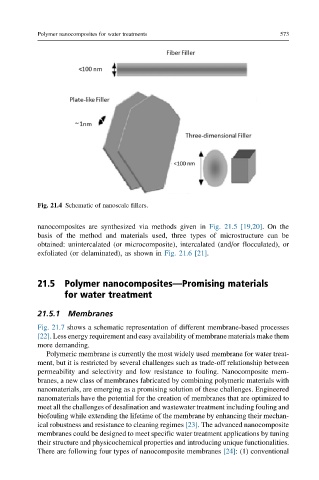

Fig. 21.4 Schematic of nanoscale fillers.

nanocomposites are synthesized via methods given in Fig. 21.5 [19,20]. On the

basis of the method and materials used, three types of microstructure can be

obtained: unintercalated (or microcomposite), intercalated (and/or flocculated), or

exfoliated (or delaminated), as shown in Fig. 21.6 [21].

21.5 Polymer nanocomposites—Promising materials

for water treatment

21.5.1 Membranes

Fig. 21.7 shows a schematic representation of different membrane-based processes

[22]. Less energy requirement and easy availability of membrane materials make them

more demanding.

Polymeric membrane is currently the most widely used membrane for water treat-

ment, but it is restricted by several challenges such as trade-off relationship between

permeability and selectivity and low resistance to fouling. Nanocomposite mem-

branes, a new class of membranes fabricated by combining polymeric materials with

nanomaterials, are emerging as a promising solution of these challenges. Engineered

nanomaterials have the potential for the creation of membranes that are optimized to

meet all the challenges of desalination and wastewater treatment including fouling and

biofouling while extending the lifetime of the membrane by enhancing their mechan-

ical robustness and resistance to cleaning regimes [23]. The advanced nanocomposite

membranes could be designed to meet specific water treatment applications by tuning

their structure and physicochemical properties and introducing unique functionalities.

There are following four types of nanocomposite membranes [24]: (1) conventional