Page 13 - Power Electronics Handbook

P. 13

6 Power semiconductor devices

A- Pull and rolaie mechanltm

M-

Growing crystal

000 flkseed crystal

Molten zone Silicon crystal Silica linei

Melt

healing

coil

AF

v

(E)

Ib) Graohite crucible

Crystal

0 RF heating coil

0

0

0 0

I

Silicon bar Meil I

(4

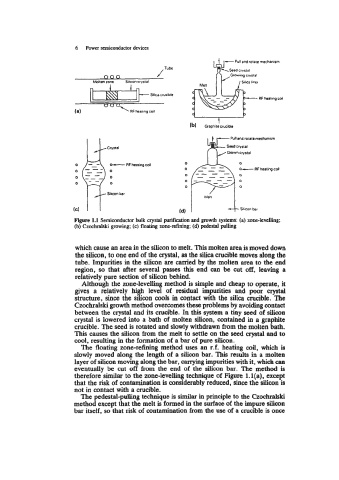

Figure 1.1 Semiconductor bulk crystal purification and growth systems: (a) zone-levelling;

(b) Czochralski growing; (c) floating zone-refining; (d) pedestal pulling

which cause an area in the silicon to melt. This molten area is moved down

the silicon, to one end of the crystal, as the silica crucible moves along the

tube. Impurities in the silicon are camed by the molten area to the end

region, so that after several passes this end can be cut off, leaving a

relatively pure section of silicon behind.

Although the zone-levelling method is simple and cheap to operate, it

gives a relatively high level of residual impurities and poor crystal

structure, since the silicon cools in contact with the silica crucible. The

Czochralski growth method overcomes these problems by avoiding contact

between the crystal and its crucible. In this system a tiny seed of silicon

crystal is lowered into a bath of molten silicon, contained in a graphite

crucible. The seed is rotated and slowly withdrawn from the molten bath.

This causes the silicon from the melt to settle on the seed crystal and to

cool, resulting in the formation of a bar of pure silicon.

The floating zone-refining method uses an r.f. heating coil, which is

slowly moved along the length of a silicon bar. This results in a molten

layer of silicon moving along the bar, carrying impurities with it, which can

eventually be cut off from the end of the silicon bar. The method is

therefore similar to the zone-levelling technique of Figure l.l(a), except

that the risk of contamination is considerably reduced, since the silicon is

not in contact with a crucible.

The pedestal-pulling technique is similar in principle to the Czochralski

method except that the melt is formed in the surface of the impure silicon

bar itself, so that risk of contamination from the use of a crucible is once