Page 18 - Power Electronics Handbook

P. 18

- 11

Fabrication process

-

Mass Ion

analyser detector

? -

- - - chamber

- Wafer

Acceleration ’ Beam

ion scanner

source 1

There are several basic requirements which must be met in any

implantation system:

(i) The impurity concentration must be uniform over a given slice, and

the process must be accurately reproducible over repeated slices.

(ii) The system must have a high throughput.

(iii) The punty of the dopant must be accurately controlled. Most ion

sources produce a range of dopants in addition to the one required.

The impurities must be completely removed from the ion stream

before it reaches the silicon slice.

(iv) The energy imparted to the ions by the accelerating voltage must be

high, to enable them to penetrate the maximum distance likely to be

required.

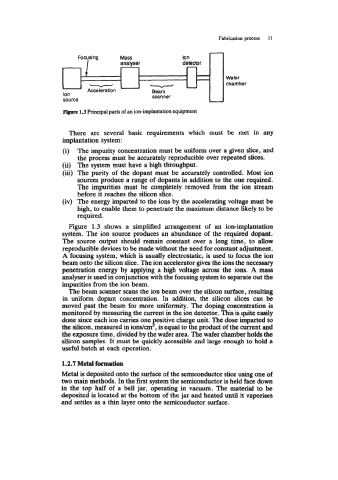

Figure 1.3 shows a simplified arrangement of an ion-implantation

system. The ion source produces an abundance of the required dopant.

The source output should remain constant over a long time, to allow

reproducible devices to be made without the need for constant adjustment.

A focusing system, which is usually electrostatic, is used to focus the ion

beam onto the silicon slice. The ion accelerator gives the ions the neceSgary

penetration energy by applying a high voltage across the ions. A mass

analyser is used in conjunction with the focusing system to separate out the

impurities from the ion beam.

The beam scanner Scans the ion beam over the silicon surface, resulting

in uniform dopant concentration. In addition, the silicon slices can be

moved past the beam for more uniformity. The doping concentration is

monitored by measuring the current in the ion detector. This is quite easily

done since each ion carries one pitive charge unit. The dose imparted to

the silicon, measured in iondcm , is equal to the product of the current and

the exposure time, divided by the wafer area. The wafer chamber holds the

silicon samples. It must be quickly accessible and large enough to hold a

useful batch at each operation.

1.2.7 Metal formation

Metal is deposited onto the surface of the semiconductor slice using one of

two main methods. In the first system the semiconductor is held face down

in the top half of a bell jar, operating in vacuum. The material to be

deposited is located at the bottom of the jar and heated until it vaporim

and settles as a thin layer onto the semiconductor surface.