Page 98 - Power Electronics Handbook

P. 98

Smartpower 91

squeegee 7

Angle of attack '\

Screen opening Paste

(a)

Paste

Screen Frame

Carriage

(c)

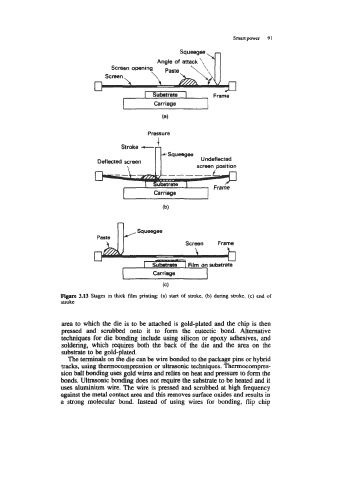

Figure 3.13 Stages in thick film printing: (a) start of stroke, e) during stroke, (c) end of

stroke

area to which the die is to be attached is gold-plated and the chip is then

pressed and scrubbed onto it to form the eutectic bond. Alternative

techniques for die bonding include using silicon or epoxy adhesives, and

soldering, which requires both the back of the die and the area on the

substrate to be gold-plated.

The terminals on the die can be wire bonded to the package pins or hybrid

tracks, using thermocompression or ultrasonic techniques. Thermocompres-

sion ball bonding uses gold wires and relies on heat and pressure to form the

bonds. Ultrasonic bonding does not require the substrate to be heated and it

uses aluminium wire. The wire is pressed and scrubbed at high frequency

against the metal contact area and this removes surface oxides and results in

a strong molecular bond. Instead of using wires for bonding, flip chip