Page 102 - Power Electronics Handbook

P. 102

Smartpower 95

(b) E> Body

Leads

(c) Leads

Chip

Ceramic cover

Metal lead frame

(4

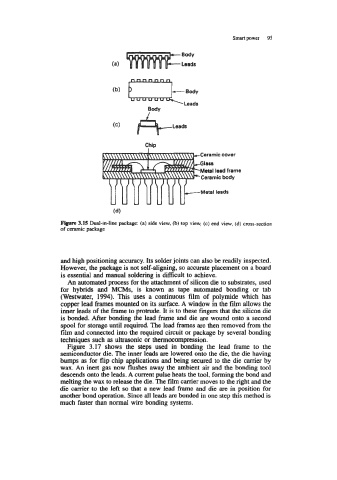

Figure 3.15 Dual-in-line package: (a) side view, (b) top view, (c) end view, (d) cross-section

of ceramic package

and high positioning accuracy. Its solder joints can also be readily inspected.

However, the package is not self-aligning, so accurate placement on a board

is essential and manual soldering is difficult to achieve.

An automated process for the attachment of silicon die to substrates, used

for hybrids and MCMs, is known as tape automated bonding or tab

(Westwater, 1994). This uses a continuous film of polymide which has

copper lead frames mounted on its surface. A window in the film allows the

inner leads of the frame to protrude. It is to these fingers that the silicon die

is bonded. After bonding the lead frame and die are wound onto a second

spool for storage until required. The lead frames are then removed from the

film and connected into the required circuit or package by several bonding

techniques such as ultrasonic or thennocompression.

Figure 3.17 shows the steps used in bonding the lead frame to the

semiconductor die. The inner leads are lowered onto the die, the die having

bumps as for flip chip applications and being secured to the die carrier by

wax. An inert gas now flushes away the ambient air and the bonding tool

descends onto the leads. A current pulse heats the tool, forming the bond and

melting the wax to release the die. The film carrier moves to the right and the

die carrier to the left so that a new lead frame and die are in position for

another bond operation. Since all leads are bonded in one step this method is

much faster than normal wire bonding systems.