Page 143 - Practical Design Ships and Floating Structures

P. 143

118

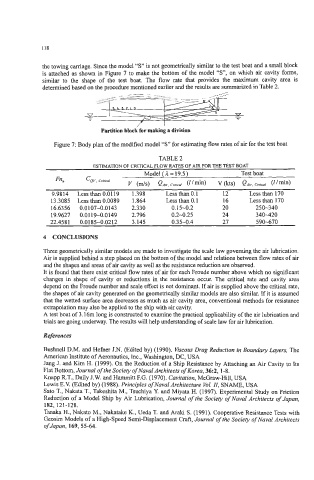

the towing carriage. Since the model “S” is not geometrically similar to the test boat and a small block

is attached as shown in Figure 7 to make the bottom of the model “S, on which air cavity forms,

similar to the shape of the test boat. The flow rate that provides the maximum cavity area is

determined based on the procedure mentioned earlier and the results are summarized in Table 2.

-- -

I

Partition block for making a division

Figure 7: Body plan of the modified model “s” for estimating flow rates of air for the test boat

TABLE 2

ESTIMATION OF CRITICAL FLOW RATES OF AIR FOR THE TEST BOAT

Model (2 = 19.5) Test boat

Fn, e,, crtrtco1

v (&s) Qm. cnrm/ (I /min) V (kt~) QAv. cnrtcal (I /min)

9.9814 Less than 0.0119 1.398 Less than 0.1 12 Less than 170

13.3085 Less than 0.0089 1.864 Less than 0.1 16 Less than 170

16.6356 0.0107-0.0143 2.330 0.15-0.2 20 250-340

19.9627 0.0119-0.0149 2.796 0.2-0.25 24 340-420

22.458 1 0.01 85-0.0212 3.145 0.35-0.4 27 590-670

4 CONCLUSIONS

Three geometrically similar models are made to investigate the scale law governing the air lubrication.

Air is supplied behind a step placed on the bottom of the model and relations between flow rates of air

and the shapes and areas of air cavity as well as the resistance reduction are observed.

It is found that there exist critical flow rates of air for each Froude number above which no significant

changes in shape of cavity or reductions in the resistance occur. The critical rate and cavity area

depend on the Froude number and scale effect is not dominant. If air is supplied above the critical rate,

the shapes of air cavity generated on the geometrically similar models are also similar. If it is assumed

that the wetted surface area decreases as much as air cavity area, conventional methods for resistance

extrapolation may also be applied to the ship with air cavity.

A test boat of 3.16m long is constructed to examine the practical applicability of the air lubrication and

trials are going underway. The results will help understanding of scale law for air lubrication.

References

Bushnell D.M. and Heher J.N. (Edited by) (1990). viscous Drag Reduction in Boundary Layers, The

American Institute of Aeronautics, Inc., Washington, DC, USA

Jang J. and Kim H. (1999). On the Reduction of a Ship Resistance by Attaching an Air Cavity to Its

Flat Bottom, Journal of the Sociery of Naval Architects of Korea, 36:2,1-8.

Knapp R.T., Daily J.W. and Hammitt F.G. (1970). Cavitation, McGraw-Hill, USA

Lewis E.V. (Edited by) (1988). Principles of Naval Architecture Vol. ZZ, SNAME, USA

Sat0 T., Nakata T., Takeshita M., Tsuchiya Y. and Miyata H. (1997). Experimental Study on Friction

Reduction of a Model Ship by Air Lubrication, Journal of the Society of Naval Architects of Japan,

182, 121-128.

Tanaka H., Nakato M., Nakatake K., Ueda T. and Araki S. (1991). Cooperative Resistance Tests with

Geosim Models of a High-speed Semi-Displacement Craft, Journal ofthe Society of Naval Architects

of Japan, 169,55-64.