Page 304 - Practical Design Ships and Floating Structures

P. 304

279

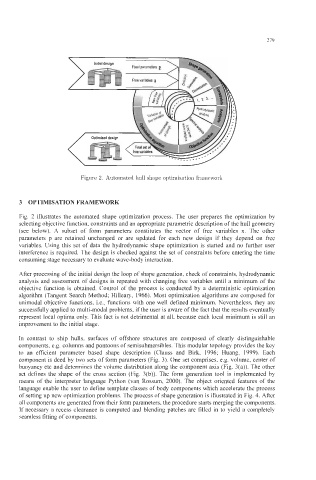

Figure 2. Automated hull shape optimisation framework

3 OPTIMISATION FRAMEWORK

Fig. 2 illustrates the automated shape optimization process. The user prepares the optimization by

selecting objective function, constraints and an appropriate parametric description of the hull geometry

(see below). A subset of form parameters constitutes the vector of free variables x. The other

parameters p are retained unchanged or are updated for each new design if they depend on free

variables. Using this set of data the hydrodynamic shape optimization is started and no further user

interference is required. The design is checked against the set of constraints before entering the time

consuming stage necessary to evaluate wave-body interaction.

After processing of the initial design the loop of shape generation, check of constraints, hydrodynamic

analysis and assessment of designs is repeated with changing free variables until a minimum of the

objective function is obtained. Control of the process is conducted by a deterministic optimization

algorithm (Tangent Search Method; Hilleary, 1966). Most optimization algorithms are composed for

unimodal objective functions, Le., functions with one well defined minimum. Nevertheless, they are

successfully applied to multi-modal problems, if the user is aware of the fact that the results eventually

represent local optima only. This fact is not detrimental at all, because each local minimum is still an

improvement to the initial stage.

In contrast to ship hulls, surfaces of offshore structures are composed of clearly distinguishable

components, e.g. columns and pontoons of semisubmersibles. This modular topology provides the key

to an efficient parameter based shape description (Clauss and Birk, 1996; Huang, 1999). Each

component is deed by two sets of form parameters (Fig. 3). One set comprises, e.g. volume, center of

buoyancy etc and determines the volume distribution along the component axis (Fig. 3(a)). The other

set defines the shape of the cross section (Fig. 3(b)). The form generation tool is implemented by

means of the interpreter language Python (van Rossum, 2000). The object oriented features of the

language enable the user to define template classes of body components which accelerate the process

of setting up new optimization problems. The process of shape generation is illustrated in Fig. 4. After

all components are generated from their form parameters, the procedure starts merging the components.

If necessary a recess clearance is computed and blending patches are filled in to yield a completely

seamless fitting of components.