Page 118 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 118

Installation, Maintenance, and Repair of Krtical Pumps 103

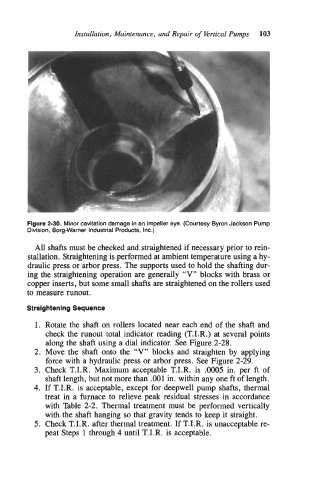

Figure 2-30. Minor cavitation damage in an impeller eye. (Courtesy Byron Jackson Pump

Division, Borg-Warner Industrial Products, Inc.)

All shafts must be checked and straightened if necessary prior to rein-

stallation. Straightening is performed at ambient temperature using a hy-

draulic press or arbor press. The supports used to hold the shafting dur-

ing the straightening operation are generally “V” blocks with brass or

copper inserts, but some small shafts are straightened on the rollers used

to measure runout.

Straightening Sequence

1. Rotate the shaft on rollers located near each end of the shaft and

check the runout total indicator reading (T.I.R.) at several points

along the shaft using a dial indicator. See Figure 2-28.

2. Move the shaft onto the “V” blocks and straighten by applying

force with a hydraulic press or arbor press. See Figure 2-29.

3. Check T.I.R. Maximum acceptable T.I.R. is .0005 in. per ft of

shaft length, but not more than BO1 in. within any one ft of length.

4. If T.I.R. is acceptable, except for deepwell pump shafts, thermal

treat in a furnace to relieve peak residual stresses in accordance

with Table 2-2. Thermal treatment must be performed vertically

with the shaft hanging so that gravity tends to keep it straight.

5. Check T.I.R. after thermal treatment. If T.I.R. is unacceptable re-

peat Steps 1 through 4 until T.I.R. is acceptable.