Page 115 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 115

100 Major Process Equipment Maintenance and Repair

9. Repeat Steps 4 through 8 to size the split rings for each succeeding

stage.

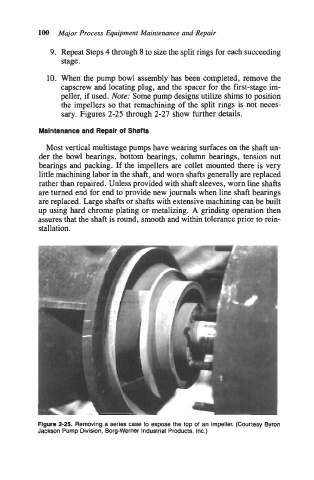

10. When the pump bowl assembly has been completed, remove the

capscrew and locating plug, and the spacer for the first-stage im-

peller, if used. Note: Some pump designs utilize shims to position

the impellers so that remachining of the split rings is not neces-

sary. Figures 2-25 through 2-27 show further details.

Maintenance and Repair of Shafts

Most vertical multistage pumps have wearing surfaces on the shaft un-

der the bowl bearings, bottom bearings, column bearings, tension nut

bearings and packing. If the impellers are collet mounted there is very

little machining labor in the shaft, and worn shafts generally are replaced

rather than repaired. Unless provided with shaft sleeves, worn line shafts

are turned end for end to provide new journals when line shaft bearings

are replaced. Large shafts or shafts with extensive machining can be built

up using hard chrome plating or metalizing. A grinding operation then

assures that the shaft is round, smooth and within tolerance prior to rein-

stallation.

Figure 2-25. Removing a series case to expose the top of an impeller. (Courtesy Byron

Jackson Pump Division, Borg-Warner Industrial Products, Inc.)