Page 112 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 112

Installation, Maintenance, and Repair of Vertical Pumps 97

split ring, to locate the impeller axially and transmit axial thrust from the

impeller to the shaft. Split rings are superior. If snap rings are used, they

should be confined so that impeller thrust does not make them tend to pop

out of the snap ring groove. The fit between the impeller and the shaft

should be a snug sliding fit.

For multi-stage pumps with semi-open impellers, correct sizing of split

rings is essential to ensure maximum pump efficiency and trouble-free

operation. Original split rings are individually sized at the factory during

pump assembly to precisely locate the impellers. Used split rings, when

reused, must be installed only with the same impellers, and in their origi-

nal location and orientation. Always use new split rings whenever the

pump shaft, cases or impellers are replaced. Machine new split rings to

size, or verify the correct sizing of used split rings, as follows:

1. T-section split rings with thrust collars are shown in Figure 2-23.

2. When feasible, assemble the pump bowl assembly in a vertical po-

sition to assure the most accurate split ring sizing. During horizon-

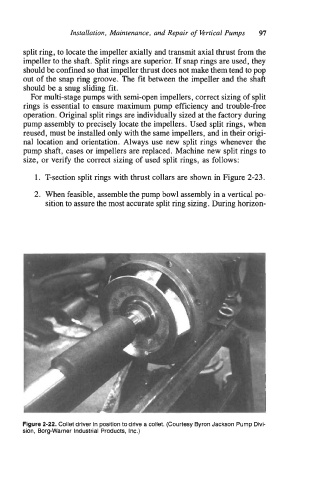

Figure 2-22. Collet driver in position to drive a collet. (Courtesy Byron Jackson Pump Divi-

sion, Borg-Warner Industrial Products, Inc.)