Page 110 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 110

Installation, Maintenance, and Repair of Wrrical Pumps 95

LOCATING PLUG

CAPSCREW PLUG BOWL

PLUG SIZE THREAD SHAFT

SIZE A B C D E SIZE

‘2 “16 1’2 1’4 JS 34” 14 RH ’%6 & 1“

I B i

BREAK ~LL snnw CORNERS

Figum 2-19. Dimensions for shaft locating plug.

BOTTOM CASE

COLLET

LOCATING

PLUG

CAP SCREW

2 114 LENGTH)

- -BOTTOM CASE

BEARING

SAND CAP

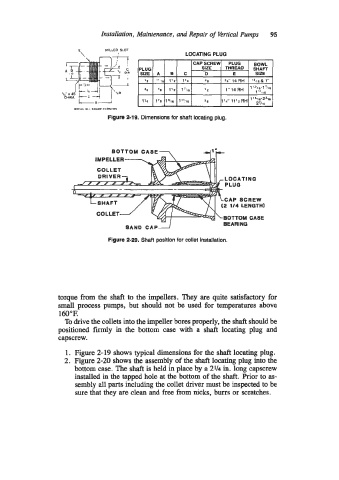

Figure 2-20. Shaft position for collet installation.

torque from the shaft to the impellers. They are quite satisfactory for

small process pumps, but should not be used for temperatures above

160°F.

To drive the collets into the impeller bores properly, the shaft should be

positioned firmly in the bottom case with a shaft locating plug and

capscrew.

1. Figure 2-19 shows typical dimensions for the shaft locating plug.

2. Figure 2-20 shows the assembly of the shaft locating plug into the

bottom case. The shaft is held in place by a 2% in. long capscrew

installed in the tapped hole at the bottom of the shaft. Prior to as-

sembly all parts including the collet driver must be inspected to be

sure that they are clean and free from nicb, burrs or scratches.