Page 151 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 151

Reciprocating and Liquid Ring kcuum Pumps 133

Maintenance of Liquid Ring Vacuum Pumps’

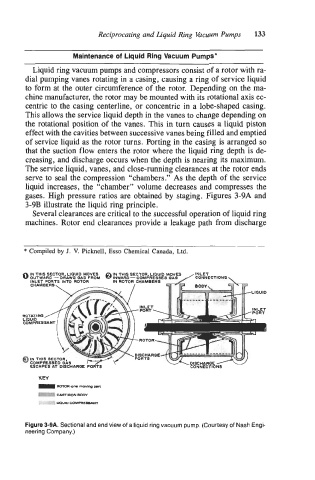

Liquid ring vacuum pumps and compressors consist of a rotor with ra-

dial pumping vanes rotating in a casing, causing a ring of service liquid

to form at the outer circumference of the rotor. Depending on the ma-

chine manufacturer, the rotor may be mounted with its rotational axis ec-

centric to the casing centerline, or concentric in a lobe-shaped casing.

This allows the service liquid depth in the vanes to change depending on

the rotational position of the vanes. This in turn causes a liquid piston

effect with the cavities between successive vanes being filled and emptied

of service liquid as the rotor turns. Porting in the casing is arranged so

that the suction flow enters the rotor where the liquid ring depth is de-

creasing, and discharge occurs when the depth is nearing its maximum.

The service liquid, vanes, and close-running clearances at the rotor ends

serve to seal the compression “chambers.” As the depth of the service

liquid increases, the “chamber” volume decreases and compresses the

gases. High pressure ratios are obtained by staging. Figures 3-9A and

3-9B illustrate the liquid ring principle.

Several clearances are critical to the successful operation of liquid ring

machines. Rotor end clearances provide a leakage path from discharge

* Compiled by J. V. Picknell, Esso Chemical Canada, Ltd.

Figure 3-9A. Sectional and end view of a liquid ring vacuum pump. (Courtesy of Nash Engi-

neering Company.)