Page 154 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 154

136 Major Process Quipment Maintenance and Repair

dictate it. Close attention to the maintenance of flushing and buffer fluid

systems is necessary to ensure long life of the seals. Seal failure can re-

sult in significant reduction in vacuum pump capacity with no visible ex-

ternal leakage.

Performance of liquid ring machines can be significantly affected by

the service liquid used. The volume of liquid employed alters the sub-

mergence of the rotor vane tips throughout the compression cycle and

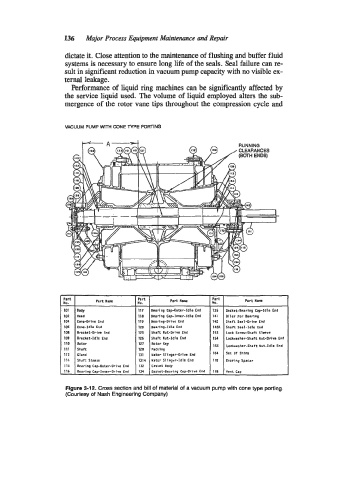

VkCUUM PUMP WITH CONE TYPE PORTING

Part Part Wma NO. I Part Nune Part I Part name

Part

NO. NO.

I01 Body 117 Bearing Cap-Outer-Idle End 135 Gasket-Bearing Cap-ldle End

102 Head 118 Bearlng Cap-lnner-ldle End 141 Oiler For Bearing

104 Cone-Drive End 119 , Bearlng-Drive End 142 Shaft Seal-Drlve End

105 Cone-Idle End 120 Bearing-Idle End 142A ShdR Seal-Idle End

108 Bracket-Drive End 125 ~ shaft WUt-DTive End 153 Lock Screw-Shaft Sleeve

109 Bracket-Idle End 126 'Shaft Nut-Idle End 154 Lockwarher-Shaft Nut-Drive End

110 Rotor 127 Rotor kky 155 LocL*uskr-Shaft Nut-Idle End

111 Shaft 128 Packlng

112 Gland 131 Hater Slinger-Drlve End 164 Set Of Shim

111 Shaf: Jlcerr 1311 H3ter Sling-r-Idle End IM kdrinp Spaczr

115 Bearing Cap-WUr-Drivm End I32 G15ket Body

116 Bearlnm C.n-Innr-Drlve End 134 I Gasket-llearlna C.0-Drive End 178 Vent Can

Figure 3-12. Cross section and bill of material of a vacuum pump with cone type porting.

(Courtesy of Nash Engineering Company)