Page 153 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 153

Reciprocating and Liquid Ring Vacuum Pumps 135

Also important is the service water temperature rise which can have an

effect on the performance of liquid ring vacuum pumps. Figure 3-10 is

typical of this interaction.

The importance of rotor end clearances in most designs necessitates

particular care in rotor axial positioning while assembling, and attention

to bearing fits so that the rotor cannot change position other than by ther-

mal growth. This becomes more difficult, but equally important in multi-

staged machines. During operation of the machines, bearing care is im-

portant to ensure that the rotor does not shift. Adequate lubrication and

vibration, shock pulse and/or spike energy monitoring is important. Most

liquid ring machines employ tight running clearances over fairly large

areas (Le., the entire rotor end area at both ends). Bearing failures result-

ing in axial or radial position changes can result in rubs and seizure of the

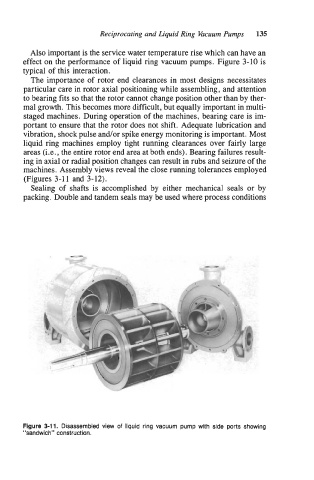

machines. Assembly views reveal the close running tolerances employed

(Figures 3-1 1 and 3-12).

Sealing of shafts is accomplished by either mechanical seals or by

packing. Double and tandem seals may be used where process conditions

Figure 3-11. Disassembled view of liquid ring vacuum pump with side ports showing

“sandwich” construction.