Page 156 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 156

138 Major Process Equipment Maintenance ond Repair

cess conditions will allow), or using pump parts made of materials resis-

tant to cavitation damage, such as high-chrome steels.

Maintenance of liquid ring machines is minimized because there are no

wearing parts other than bearings and seals. The bulk of necessary main-

tenance efforts should be aimed at the service water, seal fluid, and pres-

sure regulating systems. This necessitates careful monitoring by operat-

ing personnel. In addition to these it is necessary to monitor bearing

health by vibration analysis, shock pulse, or spike energy methods.

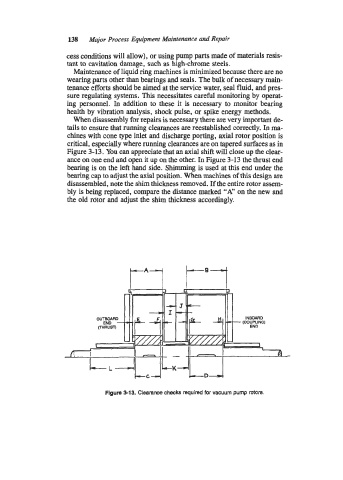

When disassembly for repairs is necessary there are very important de-

tails to ensure that running clearances are reestablished correctly. In ma-

chines with cone type inlet and discharge porting, axial rotor position is

critical, especially where running clearances are on tapered surfaces as in

Figure 3-13. You can appreciate that an axial shift will close up the clear-

ance on one end and open it up on the other. In Figure 3-13 the thrust end

bearing is on the left hand side. Shimming is used at this end under the

bearing cap to adjust the axial position. When machines of this design are

disassembled, note the shim thickness removed. If the entire rotor assem-

bly is being replaced, compare the distance marked "A" on the new and

the old rotor and adjust the shim thickness accordingly.

t-*1 t--7

Figure 513. Clearance checks required for vacuum pump rotors.