Page 181 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 181

Positive Displacement and Dynamic Blowers 163

For a dual drive unit, the driver that will operate longer is set perfectly

level on the held bearing end of the shaft and the driver that will operate

for shorter durations is placed on the free bearing end of the shaft.

Housing Completion

With the wheel and shaft in place in the bearings, erect the remaining

housing sections. Place the gasketing material shipped with the unit at the

split sections and assemble. If necessary, use a drift pin (moderately) to

align bolt holes. No gasketing is to be used at the intersection of the inlet

boxes and housing or at inlet cones. Gasket material is to be used at the

split section of the housing only. If a special housing section is to be

welded, the matching sections have bolt-through position clips that en-

sure a correct match and hold the section until seal welding is completed.

Both bolted and welded inlet boxes are used. For welded styles that

cannot be shipped attached because of freight limitations, positioning

clips on the fan housing orient the box until seal welding is completed.

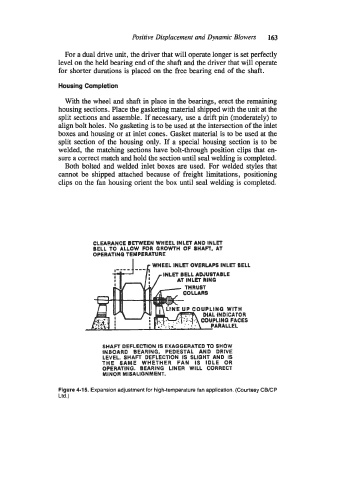

CLEARANCE BETWEEN WHEEL INLET AND INLET

BELL TO ALLOW FOR GROWTH OF SHAFT. AT

OPERATINO TEMPERATURE

WHEEL INLET OVERLAPS INLET BELL

INLET BELL ADJUSTABLE

AT INLET RING

I

E . 'LI NQ WITH

IAL INC WATOR

*

1

I ARA ,LLEL

A

SHAFT DEFLECTION IS EXAGGERATED TO SHOW

INBOARD BEARING, PEDESTAL AND DRIVE

LEVEL. SHAFT DEFLECTION IS SLIGHT AND IS

THE SAME WHETHER FAN IS IDLE OR

OPERATING. BEARING LINER WILL CORRECT

MINOR MISALIGNMENT.

Figure 4-15. Expansion adjustmen! for high-temperature fan application. (Courtesy CBKP

Ltd.)