Page 331 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 331

Installation and Maintenance of VBelr Drives 311

Any vibration in a system will cause the slack side of the belts to dance

up and down. Excessive vibration will also induce a vibration in the tight

side of the drive. The cause of the vibration should be determined and

corrected.

If a set of belts is perfectly matched, all belts will have the same

amount of sag. However, perfection is a rare thing and there will usually

exist some difference in sag from belt to belt. It is more important to look

at the tight side of a drive to be sure that all of the belts are running tight.

If one or more belts are running loose, the drive needs to be retensioned,

or the belts replaced with a matched set.

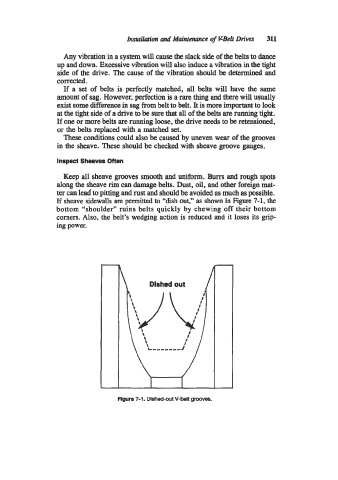

These conditions could also be caused by uneven wear of the grooves

in the sheave. These should be checked with sheave groove gauges.

Inspect Sheave8 Often

Keep all sheave grooves smooth and uniform. Burrs and rough spots

along the sheave rim can damage belts. Dust, oil, and other foreign mat-

ter can lead to pitting and rust and should be avoided as much as possible.

If sheave sidewalls are permitted to “dish out,” as shown in Figure 7-1, the

bottom “shoulder” ruins belts quickly by chewing off their bottom

comers. Also, the belt’s wedging action is reduced and it loses its grip-

ing power.

Figure 7-1. Dished-out V-belt grooves.