Page 332 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 332

312 Major Process Equipment Maintenance and Repair

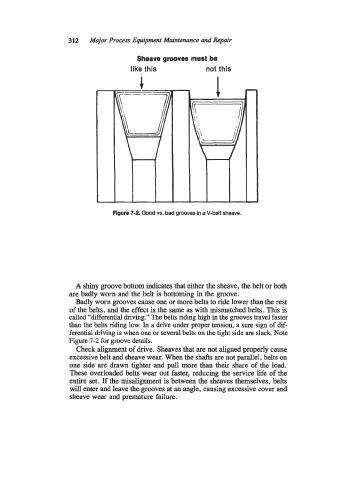

Sheave grooves must be

like this not this

I

Figure 7-2. Good vs. bad grooves in a V-belt sheave.

A shiny groove bottom indicates that either the sheave, the belt or both

are badly worn and the belt is bottoming in the groove.

Badly worn grooves cause one or more belts to ride lower than the rest

of the belts, and the effect is the same as with mismatched belts. This is

called “differential driving.” The belts riding high in the grooves travel faster

than the belts riding low. In a drive under proper tension, a sure sign of dif-

ferential driving is when one or several belts on the tight side are slack. Note

Figure 7-2 for groove details.

Check alignment of drive. Sheaves that are not aligned properly cause

excessive belt and sheave wear. When the shafts are not parallel, belts on

one side are drawn tighter and pull more than their share of the load.

These overloaded belts wear out faster, reducing the service life of the

entire set. If the misalignment is between the sheaves themselves, belts

will enter and leave the grooves at an angle, causing excessive cover and

sheave wear and premature failure.