Page 335 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 335

Installation and Maintenance of V-Belt Drives 315

by belts that are either too tight or too loose. Check the tension carefully

using the instructions furnished.

If the belts are slipping on your drive, retension the drive. Never use

belt dressing to correct slipping belts.

Maintain Proper Belt Tension

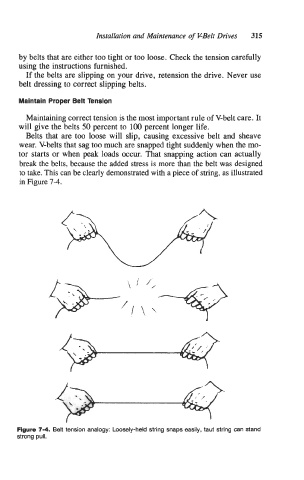

Maintaining correct tension is the most important rule of V-belt care. It

will give the belts 50 percent to 100 percent longer life.

Belts that are too loose will slip, causing excessive belt and sheave

wear. V-belts that sag too much are snapped tight suddenly when the mo-

tor starts or when peak loads occur. That snapping action can actually

break the belts, because the added stress is more than the belt was designed

to take. This can be clearly demonstrated with a piece of string, as illustrated

in Figure 7-4.

Figure 7-4. Belt tension analogy: Loosely-held string snaps easily, taut string can stand

strong pull.