Page 340 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 340

320 Major Process Equipment Maintenance and Repair

# R i g -8

#q -#

'#- -#

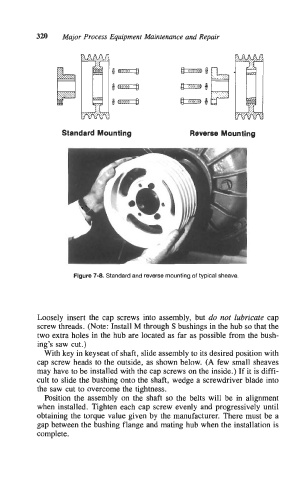

Standard Mounting Reverse Mounting

Figure 7-8. Standard and reverse mounting of typical sheave.

Loosely insert the cap screws into assembly, but do not lubricate cap

screw threads. (Note: Install M through S bushings in the hub so that the

two extra holes in the hub are located as far as possible from the bush-

ing's saw cut.)

With key in keyseat of shaft, slide assembly to its desired position with

cap screw heads to the outside, as shown below. (A few small sheaves

may have to be installed with the cap screws on the inside.) If it is diffi-

cult to slide the bushing onto the shaft, wedge a screwdriver blade into

the saw cut to overcome the tightness.

Position the assembly on the shaft so the belts will be in alignment

when installed. Tighten each cap screw evenly and progressively until

obtaining the torque value given by the manufacturer. There must be a

gap between the bushing flange and mating hub when the installation is

complete.