Page 342 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 342

322 Major Process Equipment Maintenance and Repair

Remove mating part from bushing and, if necessary, bushing from

shaft. If bushing won’t slip off shaft, wedge screwdriver blade in saw cut

to overcome tightness.

Alignment Checking

Although alignment is not as critical in V-belt drives as in others proper

alignment is essential to long belt and sheave life.

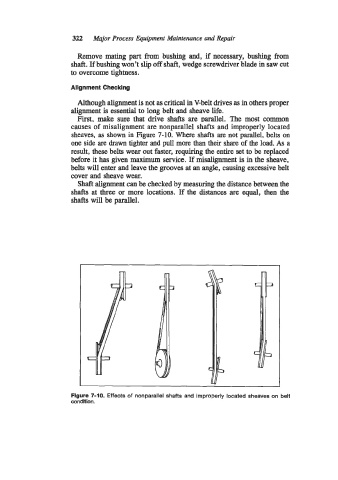

First. make sure that drive shafts are parallel. The most common

causes of misalignment are nonparallel shafts and improperly located

sheaves, as shown in Figure 7-10. Where shafts are not parallel, belts on

one side are drawn tighter and pull more than their share of the load. As a

result, these belts wear out faster, requiring the entire set to be replaced

before it has given maximum service. If misalignment is in the sheave,

belts will enter and leave the grooves at an angle, causing excessive belt

cover and sheave wear.

Shaft alignment can be checked by measuring the distance between the

shafts at three or more locations. If the distances are equal, then the

shafts will be parallel.

Figure 7-10. Effects of nonparallel shafts and improperly located sheaves on belt

condition.