Page 345 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 345

Installation and Maintenance of VBelt Drives 325

Tenslonlng by General Method

The general method for tensioning V-belts should satisfy most drive re-

quirements :

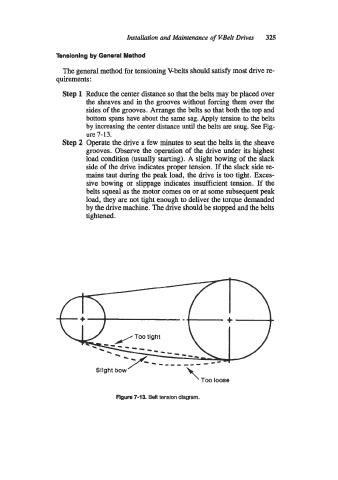

Step 1 Reduce the center distance so that the belts may be placed over

the sheaves and in the grooves without forcing them over the

sides of the grooves. Arrange the belts so that both the top and

bottom spans have about the same sag. Apply tension to the belts

by increasing the center distance until the belts are snug. See Fig-

UR 7-13.

Step 2 Operate the drive a few minutes to seat the belts in the sheave

grooves. Observe the operation of the drive under it3 highest

load condition (usually starting). A slight bowing of the slack

side of the drive indicates proper tension. If the slack side re-

mains taut during the peak load, the drive is too tight. Exces-

sive bowing or slippage indicates insufficient tension. If the

belts squeal as the motor comes on or at some subsequent peak

load, they are not tight enough to deliver the torque demanded

by the drive machine. The drive should be stopped and the belts

tightened.

figure 7-13. Belt tension diagram.