Page 341 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 341

Installation and Maintenance of VBelt Drives 321

Typical Sheave and Bushing Removal Instruction

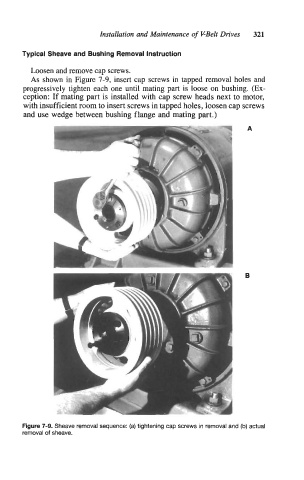

Loosen and remove cap screws.

As shown in Figure 7-9, insert cap screws in tapped removal holes and

progressively tighten each one until mating part is loose on bushing. (Ex-

ception: If mating part is installed with cap screw heads next to motor,

with insufficient room to insert screws in tapped holes, loosen cap screws

and use wedge between bushing flange and mating part.)

A

B

Figure 7-9. Sheave removal sequence: (a) tightening cap screws in removal and (b) actual

removal of sheave.