Page 333 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 333

Pnstallation and Maintenance of VBelf Drives 313

Belt and Sheave Gauges

Belt and sheave groove gauge sets are available from your distributor

and should be in your tool set.

You can use them to determine the proper belt section by trying the old

belt in the various gauges until a proper fit is obtained. The cross section

of conventional or narrow-wedge belts can be read from the gauge.

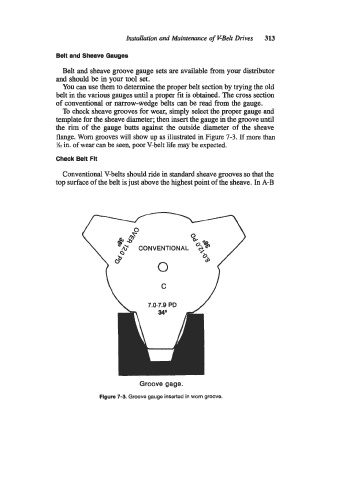

To check sheave grooves for wear, simply select the proper gauge and

template for the sheave diameter; then insert the gauge in the groove until

the rim of the gauge butts against the outside diameter of the sheave

flange. Worn grooves will show up as illustrated in Figure 7-3. If more than

% in. of wear can be seen, poor V-belt life may be expected.

Check Belt Fit

Conventional V-belts should ride in standard sheave grooves so that the

top surface of the belt is just above the highest point of the sheave. In A-B

8 %

A

!$ CONVENTIONAL 0. %

\ 7.0-7.9 PD /

Groove gage.

Figure 7-3. Groove gauge inserted in worn groove.