Page 419 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 419

Steam Turbines and Turboqanders 397

4. Apply a combination of paste and plastic string sealants to the seal-

ing surfaces of the steam chest valve cover flange.

5. Return the valve assembly and cover to the steam chest body and

tighten the cap screws (4).

6. Backseat the trip valve per Backseating the Trip Valve Section, and

connect the closing spring (14 and 49) to the resetting lever (11).

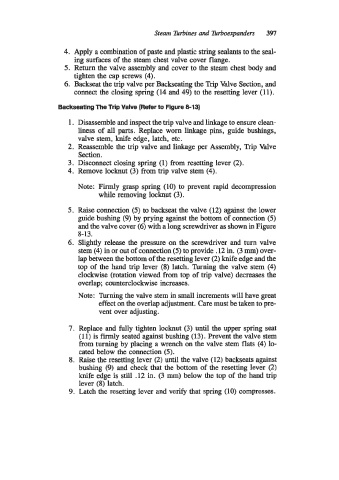

Backseating The Trip Valve (Refer to Figure 8-13)

1. Disassemble and inspect the trip valve and linkage to ensure clean-

liness of all parts. Replace worn linkage pins, guide bushings,

valve stem, knife edge, latch, etc.

2. Reassemble the trip valve and linkage per Assembly, Trip Valve

Section.

3. Disconnect closing spring (1) from resetting lever (2).

4. Remove locknut (3) from trip valve stem (4).

Note: Firmly grasp spring (10) to prevent rapid decompression

while removing locknut (3).

5. Raise connection (5) to backseat the valve (12) against the lower

guide bushing (9) by prying against the bottom of connection (5)

and the valve cover (6) with a long screwdriver as shown in Figure

8-13.

6. Slightly release the pressure on the screwdriver and turn valve

stem (4) in or out of connection (5) to provide .12 in. (3 mm) over-

lap between the bottom of the resetting lever (2) knife edge and the

top of the hand trip lever (8) latch. Turning the valve stem (4)

clockwise (rotation viewed from top of trip valve) decreases the

overlap; counterclockwise increases.

Note: Turning the valve stem in small increments will have great

effect on the overlap adjustment. Care must be taken to pre-

vent over adjusting.

7. Replace and fully tighten locknut (3) until the upper spring seat

(1 1) is firmly seated against bushing (13). Prevent the valve stem

from turning by placing a wrench on the valve stem flats (4) lo-

cated below the connection (5).

8. Raise the resetting lever (2) until the valve (12) backseats against

bushing (9) and check that the bottom of the resetting lever (2)

knife edge is still .12 in. (3 rnm) below the top of the hand trip

lever (8) latch.

9. Latch the resetting lever and verify that spring (10) compresses.