Page 424 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 424

402 Major Process Equipment Maintenance and Repair

mum tendency to emulsify or foam when agitated. It should have high

rust and oxidation resistance and minimum sludge, lacquer, varnish or

resin forming tendencies. In addition to these requirements, Tables 8-5 and

8-8 contain other necessary information to aid in selecting the proper lubri-

cating oil for your turbine.

%bines driving through speed reduction or increasing gears are often

pressure lubricated by the gear lubrication system. Refer to the gear man-

ufacturer's instructions for gear oil requirements.

Care of Oil

Lubricating oil should be maintained in first class condition by pre-

venting contamination from moisture, dust, dirt or other impurities. An

oil maintenance analysis program is recommended for determining the

frequency of oil changes. Consult your oil supplier for assistance in es-

tablishing a program that will meet your specific lubrication maintenance

requirements. Refer also to Chapter 12.

Methods of Lubrication

Most steam turbines are furnished with either an oil ring lubrication

system or a pressure lubrication system. Pressure lubricated turbines

~

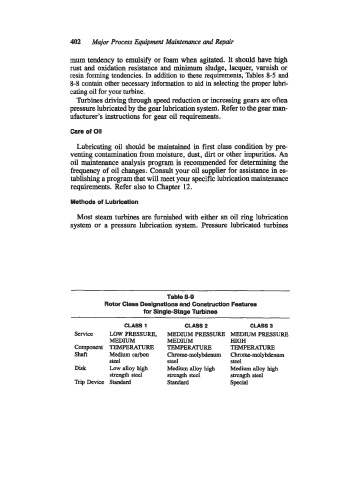

Table 8-9

Rotor Class Designations and Consbudion Features

for Single-Stage Turbines

CLASS 1 CLASS 2 CLASS 3

service Low PRESSURE, MEDIUM PRESSURE MEDIUM PRESSURE

MEDIUM MEDIUM HIGH

Component TEMPERATURE TEMPERATURE TEMPERATURE

Shaft Medium carbon Chromemolybdenum Chromemolybdenum

steel Steel steel

Disk Low alloy high Medium alloy high Medium alloy high

strength steel strength steel strength steel

TripDevice Standard Standard Special