Page 427 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 427

Steam Turbines and Turboexpanders 405

Oil Ring Lubrication (Refer to Figure 8-15)

The oil ring lubrication system is a simple system which employs oil

rings to deliver oil to the turbine bearings. The rings, approximately

twice the diameter of the shaft journals, are rotated by the journals and

carry oil from the bearing housing reservoirs to the top half bearing lin-

ers. The oil flows axially along the top liners through grooves. Rotating

journals carry the oil to the clearance between the bearing liners and the

shaft journals. Oil drains from the ends of each bearing liner and returns

to the bearing housing reservoirs to be cooled and recycled. Oil dis-

charged from the steam end journal bearing floods the rotor locating

bearing before draining into the bearing housing reservoir.

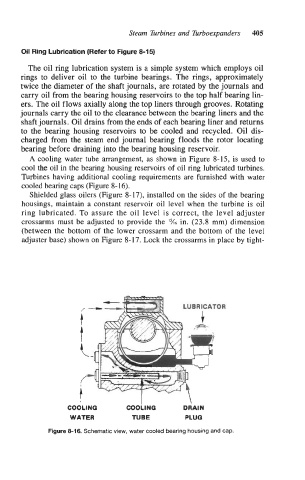

A cooling water tube arrangement, as shown in Figure 8-15, is used to

cool the oil in the bearing housing reservoirs of oil ring lubricated turbines.

Turbines having additional cooling requirements are furnished with water

cooled bearing caps (Figure 8-16).

Shielded glass oilers (Figure 8-17), installed on the sides of the bearing

housings, maintain a constant reservoir oil level when the turbine is oil

ring lubricated. To assure the oil level is correct, the level adjuster

crossarms must be adjusted to provide the ‘%6 in. (23.8 mm) dimension

(between the bottom of the lower crossarm and the bottom of the level

adjuster base) shown on Figure 8-17. Lock the crossarms in place by tight-

COOLING COOLING DRAIN

WATER TUBE PLUG

Figure 8-16. Schematic view, water cooled bearing housing and cap.