Page 428 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 428

406 Major Process Equipment Maintenance and Repair

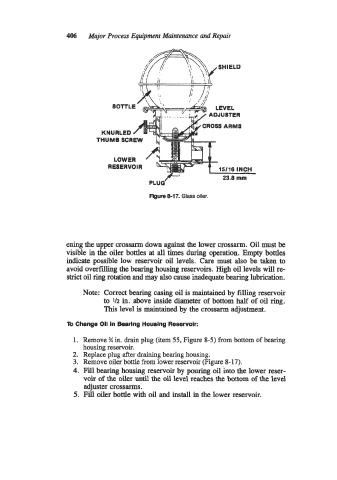

Figure 8-17. Glass oiler.

ening the upper crossarm down against the lower crossarm. Oil must be

visible in the oiler bottles at all times during aperation. Empty bottles

indicate possible low reservoir oil levels. Care must also be taken to

avoid overfilling the bearing housing reservoirs. High oil levels will re-

strict oil ring rotation and may also cause inadequate bearing lubrication.

Note: Correct bearing casing oil is maintained by filling reservoir

to 1/2 in. above inside diameter of bottom half of oil ring.

This level is maintained by the crossarm adjustment.

lb Change 011 In Bearlng Housing Reservoir:

1. Remove % in. drain plug (item 55, Figure 8-5) from bottom of bearing

housing reservoir.

2. Replace plug after draining bearing housing.

3. Remove oiler bottle from lower reservoir (Figure 8-17).

4. Fill bearing housing reservoir by pouring oil -into the lower reser-

voir of the oiler until the oil level reaches the bottom of the level

adjuster crossarms.

5. Fill oiler bottle with oil and install in the lower reservoir.