Page 81 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 81

66 Major Process Equipment Maintenance and Repair

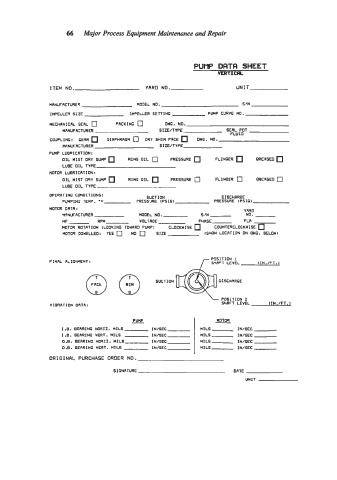

PUMP DATA SHEET

VERTICAL

ITEM NO. YARD NO. UNIT

MANUTRCTURE4 MOOEL NO. SIN

IMPELLES SiZE IMDELLER SETTING PUMP CURVE NO.

MECHANICRL SEAL 0 PACKING 0 one. NO.

MANilFRCTURER SIZE/TYPE SEAL POT

FLU ID

COUPLING: CERR OIAPHRRGM [3 DRY SHIM PACK DUG. NO.

MRNUFRCTURER SIZE/TYPE

PUMP LUB~ICATION:

OIL MIST DRY SUR RING OIL 0 PRESSURE FLINGER GREASE0

LUBE OIL TYPE

MDTOR LUBRICATION:

OIL MIST DPY SUMD RING OIL PRESSURE 0 FLINGER 0 GRERSEO 0

LUBE OIL TYPE

OPERRTING CONOITIONS: SUCTION OISCHRRGE

PWPIN; TEMP. 'E PRESS'JRE IPS161 PRESSURE IPSIGI

MOTOF! omn: ynw

~.qNUFRCTURER W~DEL NO. SIN N3.

HP.- RPM VOLTRGE PHASE FLA

MOT39 ROTATION IL03KING TOWARD PUMP1 CLOCKWISE COilNTERCLCCKYISE

MOTOS DOWELLED: TES 0 NO 0 SIZE ISL(0U LOCRTIOY ON OW:. BELDWI

0 0 01 SCHARGE

FINAL ALIGNMENT:

POSiTION 2

VIBRATION ORTA: ShRFT LEVEL IIN.IFT.1

-

PUMP MOTOF!

I.B. BEARING HORIZ. MILS IN/SEC MILS IN/SEC

I.B. BEARING VERT. MILS IN/SEC MILS- IN/SEC

O.B. BERRING HORIZ. MILS IN/SEC MILS- INISEC

O.B. BEARING VERT. MILS IN/SEC MILS- IN/SEC