Page 85 - Practical Machinery Management for Process Plants Major Process Equipment Maintenance and Repair

P. 85

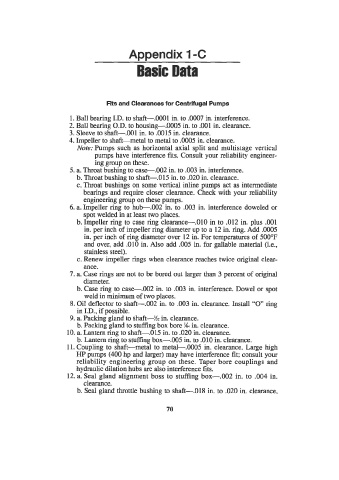

Appendix 1 -C

Basic Data

Fits and Clearances for Centrifugal Pumps

1. Ball bearing I.D. to shaft-.0001 in. to .0007 in. interference.

2. Ball bearing O.D. to housing-.0005 in. to .001 in. clearance.

3. Sleeve to shaft-.001 in. to .0015 in. clearance.

4. Inipeller to shaft-metal to metal to .0005 in. clearance.

Note: Pumps such as horizontal axial split and multistage vertical

pumps have interference fits. Consult your reliability engineer-

ing group on these.

5. a. Throat bushing to case.002 in. to .003 in. interference.

b. Throat bushing to shaft-.015 in. to .020 in. clearance.

c. Throat bushings on some vertical inline pumps act as intermediate

bearings and require closer clearance. Check with your reliability

engineering group on these pumps.

6. a. Impeller ring to huL.002 in. to .003 in. interference doweled or

spot welded in at least two places.

b. Impeller ring to case ring clearance-.010 in to .012 in. plus .001

in. per inch of impeller ring diameter up to a 12 in. ring. Add .0005

in. per inch of ring diameter over 12 in. For temperatures of 500°F

and over, add .010 in. Also add .005 in. for gallable material (Le.,

stainless steel).

c. Renew impeller rings when clearance reaches twice original clear-

ance.

7. a. Case rings are not to be bored out larger than 3 percent of original

diameter.

b. Case ring to case-.002 in. to .003 in. interference. Dowel or spot

weld in minimum of two places.

8. Oil deflector to shaft-.002 in. to .003 in. clearance. Install “0’ ring

in I.D., if possible.

9. a. Packing gland to shaft-% in. clearance.

b. Packing gland to stuffing box bore % in. clearance.

10. a. Lantern ring to shaft-.015 in. to .020 in. clearance.

b. Lantern ring to stuffing box-.005 in. to .010 in. clearance.

11. Coupling to shaft-metal to metal-.0005 in. clearance. Large high

HP pumps (400 hp and larger) may have interference fit; consult your

reliability engineering group on these. Taper bore couplings and

hydraulic dilation hubs are also interference fits.

12. a. Seal gland alignment boss to stuffing box-.002 in. to .004 in.

clearance.

b. Seal gland throttle bushing to shaft-.018 in. to .020 in. clearance,

70